پروڈکٹ کے پیرامیٹرز

| پروڈکٹ کا نام | گرم انڈکشن موڑ |

| سائز | 1/2"-36" ہموار، 26"-110" ویلڈیڈ |

| معیاری | ANSI B16.49، ASME B16.9 اور اپنی مرضی کے مطابق وغیرہ |

| دیوار کی موٹائی | STD, XS, SCH20,SCH30,SCH40, SCH60, SCH80,SCH100,SCH120,SCH140,SCH160، XXS، اپنی مرضی کے مطابق، وغیرہ |

| کہنی | 30° 45° 60° 90° 180°، وغیرہ |

| رداس | ملٹی پلیکس رداس، 3D اور 5D زیادہ مقبول ہے، 4D، 6D، 7D بھی ہو سکتا ہے،10D، 20D، اپنی مرضی کے مطابق، وغیرہ |

| ختم | بیول اینڈ/BE/بٹ ویلڈ، ٹینجنٹ کے ساتھ یا اس کے ساتھ (ہر سرے پر سیدھا پائپ) |

| سطح | پالش، ٹھوس حل گرمی کا علاج، اینیل، اچار، وغیرہ |

| مواد | سٹینلیس سٹیل:A403 WP304/304L, A403 WP316/316L, A403 WP321, A403 WP310S،A403 WP347H, A403 WP316Ti،A403 WP317, 904L,1.4301,1.4307,1.4401,1.4571,1.4541,254Mo اور وغیرہ |

| ڈوپلیکس سٹیل:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760,1.4462,1.4410,1.4501 اور وغیرہ | |

| نکل کھوٹ سٹیل:inconel600, inconel625, inconel690, incoloy800, incoloy 825,incoloy 800H, C22, C-276, Monel400,الائے 20 وغیرہ | |

| درخواست | پیٹرو کیمیکل انڈسٹری؛ ایوی ایشن اور ایرو اسپیس انڈسٹری؛ فارماسیوٹیکل انڈسٹری،گیس کا اخراج؛ پاور پلانٹ؛ جہاز کی عمارت؛ پانی کا علاج، وغیرہ |

| فوائد | تیار اسٹاک، تیز ترسیل کا وقت؛ تمام سائز میں دستیاب، اپنی مرضی کے مطابق؛ اعلیٰ معیار |

ہاٹ انڈکشن موڑنے کے فوائد

بہتر مکینیکل خصوصیات:

گرم انڈکشن موڑ کا طریقہ کولڈ موڑ اور ویلڈیڈ سلوشنز کے ساتھ موازنہ کرتے ہوئے مین پائپ کی مکینیکل خصوصیات کو یقینی بناتا ہے۔

ویلڈ اور این ڈی ٹی کے اخراجات کو کم کرتا ہے:

گرم موڑ ویلڈز کی تعداد اور مواد پر غیر تباہ کن اخراجات اور خطرات کو کم کرنے کا ایک اچھا طریقہ ہے۔

تیز رفتار مینوفیکچرنگ:

انڈکشن موڑنے پائپ موڑنے کا ایک انتہائی مؤثر طریقہ ہے، کیونکہ یہ تیز، عین مطابق اور کچھ غلطیوں کے ساتھ ہے۔

تفصیلی تصاویر

1. ANSI B16.25 کے مطابق بیول اینڈ۔

2. ریت رولنگ، ٹھوس حل، annealled.

3. لیمینیشن اور دراڑ کے بغیر۔

4. بغیر کسی ویلڈ کی مرمت کے۔

5. ہر سرے پر ٹینجنٹ کے ساتھ یا بغیر ہو سکتا ہے، ٹینجنٹ کی لمبائی اپنی مرضی کے مطابق کی جا سکتی ہے۔

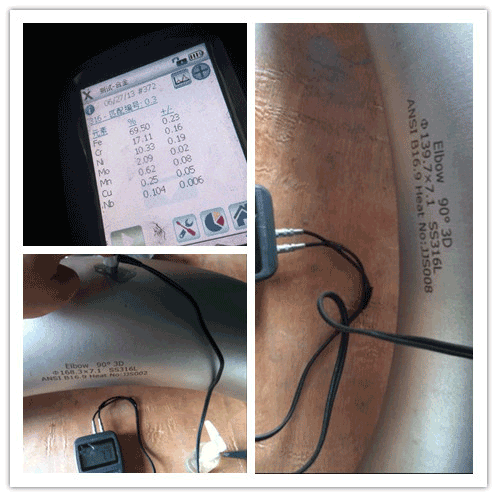

معائنہ

1. طول و عرض کی پیمائش، تمام معیاری رواداری کے اندر۔

2. موٹائی رواداری:+/-12.5%، یا آپ کی درخواست پر۔

3. پی ایم آئی۔

4. MT، UT، PT، ایکسرے ٹیسٹ۔

5. فریق ثالث کا معائنہ قبول کریں۔

6. MTC، EN10204 3.1/3.2 سرٹیفکیٹ فراہم کریں۔

پیکجنگ اور شپنگ

1. آئی ایس پی ایم 15 کے مطابق پلائیووڈ کیس یا پلائیووڈ پیلیٹ سے پیک کیا گیا ہے۔

2. ہم ہر پیکج پر پیکنگ لسٹ ڈالیں گے۔

3. ہم ہر پیکج پر شپنگ مارکنگ ڈالیں گے۔ نشانات والے الفاظ آپ کی درخواست پر ہیں۔

4. لکڑی کے تمام پیکج مواد فیومیگیشن سے پاک ہیں۔

5. شپنگ لاگت کو بچانے کے لیے، صارفین کو ہمیشہ کسی پیکج کی ضرورت نہیں ہوتی۔ موڑ کو براہ راست کنٹینر میں ڈالیں۔

سیاہ سٹیل پائپ موڑ

اسٹیل پائپ موڑنے کے ساتھ ساتھ، سیاہ سٹیل پائپ موڑ بھی پیدا کر سکتا ہے، مزید تفصیلات، براہ کرم مندرجہ ذیل لنک پر کلک کریں۔

کاربن اسٹیل، Cr-mo الائے اسٹیل اور کم مدتی کاربن اسٹیل بھی دستیاب ہیں۔

اکثر پوچھے گئے سوالات

1. SUS 304، 321، اور 316 سٹینلیس سٹیل کی کہنیاں کیا ہیں؟

SUS 304, 321 اور 316 سٹینلیس سٹیل کے مختلف درجات ہیں جو عام طور پر جھکے ہوئے پائپوں کی تیاری میں استعمال ہوتے ہیں۔ ان میں بہترین سنکنرن مزاحمت اور اعلی طاقت کی خصوصیات ہیں۔

2. 180 ڈگری کہنی کیا ہے؟

ایک 180 ڈگری کہنی ایک موڑ فٹنگ ہے جو پائپ میں سیال یا گیس کے بہاؤ کو 180 ڈگری پر ری ڈائریکٹ کرنے کے لیے استعمال ہوتی ہے۔ یہ سمت میں کسی بھی اچانک تبدیلی سے گریز کرتے ہوئے ہموار بہاؤ کی اجازت دیتا ہے۔

3. SUS 304، 321، اور 316 سٹینلیس سٹیل کہنیوں کی ایپلی کیشنز کیا ہیں؟

یہ سٹینلیس سٹیل کی کہنیاں مختلف صنعتوں جیسے کیمیکل پروسیسنگ، آئل اینڈ گیس، پیٹرو کیمیکل، پاور جنریشن، فارماسیوٹیکل اور فوڈ پروسیسنگ میں بڑے پیمانے پر استعمال ہوتی ہیں۔

4. SUS 304، 321، اور 316 سٹینلیس سٹیل کہنیوں کے استعمال کے کیا فوائد ہیں؟

SUS 304, 321 اور 316 سٹینلیس سٹیل کی کہنیوں میں بہترین سنکنرن مزاحمت، اعلی درجہ حرارت کی مزاحمت اور دباؤ کی مزاحمت ہے۔ وہ انتہائی سخت حالات میں بھی اپنی طاقت برقرار رکھتے ہیں، طویل خدمت زندگی کو یقینی بناتے ہیں۔

5. کیا SUS 304، 321، اور 316 سٹینلیس سٹیل کی کہنیوں کو ویلڈیڈ کیا جا سکتا ہے؟

جی ہاں، ان سٹینلیس سٹیل کی کہنیوں کو ویلڈنگ کی مناسب تکنیک اور آلات کا استعمال کرتے ہوئے آسانی سے ویلڈیڈ کیا جا سکتا ہے۔ تاہم، جوائنٹ کی سالمیت کو یقینی بنانے کے لیے ویلڈنگ کے مناسب طریقہ کار پر عمل کرنا ضروری ہے۔

6. کیا SUS 304، 321 اور 316 سٹینلیس سٹیل کی کہنیوں کے لیے مختلف سائز ہیں؟

ہاں، SUS 304، 321 اور 316 سٹینلیس سٹیل کی کہنیاں مختلف سائز میں دستیاب ہیں تاکہ پائپ کے مختلف قطروں اور دیوار کی موٹائی کو ایڈجسٹ کیا جا سکے۔ وہ مخصوص منصوبے کی ضروریات کو پورا کرنے کے لئے اپنی مرضی کے مطابق کیا جا سکتا ہے.

7. کیا SUS 304, 321 اور 316 سٹینلیس سٹیل کی کہنیاں ہائی پریشر ایپلی کیشنز کے لیے موزوں ہیں؟

جی ہاں، یہ سٹینلیس سٹیل کی کہنیوں کو ہائی پریشر کے حالات کو برداشت کرنے کے لیے ڈیزائن کیا گیا ہے۔ ان میں بہترین میکانی خصوصیات ہیں اور بغیر کسی خرابی یا ناکامی کے اعلی دباؤ کا مقابلہ کر سکتے ہیں۔

8. کیا SUS 304، 321، اور 316 سٹینلیس سٹیل کی کہنیوں کو سنکنرن ماحول میں استعمال کیا جا سکتا ہے؟

بالکل! SUS 304, 321 اور 316 سٹینلیس سٹیل بہترین سنکنرن مزاحمت پیش کرتے ہیں اور سنکنرن ماحول میں استعمال کے لیے مثالی ہیں، بشمول کیمیکلز، تیزاب اور نمکین پانی کی نمائش۔

9. کیا SUS 304، 321، اور 316 سٹینلیس سٹیل کی کہنیوں کو برقرار رکھنا آسان ہے؟

ہاں، SUS 304، 321 اور 316 سٹینلیس سٹیل کی کہنیوں کو برقرار رکھنا نسبتاً آسان ہے۔ باقاعدگی سے صفائی اور معائنے سے سنکنرن یا نقصان کی کسی بھی علامت کی نشاندہی کرنے میں مدد مل سکتی ہے تاکہ ضرورت پڑنے پر مرمت یا تبدیلی کی جا سکے۔

10. میں SUS 304, 321, اور 316 سٹینلیس سٹیل کہنی کے پائپ کہاں سے خرید سکتا ہوں؟

SUS 304, 321 اور 316 سٹینلیس سٹیل کی کہنیوں کو مختلف سپلائرز، ڈسٹری بیوٹرز یا مینوفیکچررز سے خریدا جا سکتا ہے جو سٹینلیس سٹیل پائپ فٹنگ میں مہارت رکھتے ہیں۔ ایک معروف سپلائر کا انتخاب کرنا ضروری ہے جو اعلیٰ معیار کی مصنوعات پیش کرتا ہو۔

پائپ کی متعلقہ اشیاء پائپنگ سسٹم میں اہم اجزاء ہیں، جو کنکشن، ری ڈائریکشن، ڈائیورشن، سائز میں تبدیلی، سیال کے بہاؤ کو سیل کرنے یا کنٹرول کرنے کے لیے استعمال ہوتے ہیں۔ ان کا استعمال بڑے پیمانے پر تعمیرات، صنعت، توانائی اور میونسپل سروسز جیسے شعبوں میں ہوتا ہے۔

کلیدی افعال:یہ پائپوں کو جوڑنے، بہاؤ کی سمت کو تبدیل کرنے، بہاؤ کو تقسیم اور ضم کرنے، پائپ کے قطر کو ایڈجسٹ کرنے، پائپوں کو سیل کرنے، کنٹرول اور ریگولیٹ کرنے جیسے کام انجام دے سکتا ہے۔

درخواست کی گنجائش:

- پانی کی فراہمی اور نکاسی آب کی تعمیر:پانی کے پائپ نیٹ ورکس کے لیے پی وی سی کہنیوں اور پی پی آر ٹریس کا استعمال کیا جاتا ہے۔

- صنعتی پائپ لائنز:سٹینلیس سٹیل کے فلینجز اور الائے سٹیل کی کہنیوں کا استعمال کیمیکل میڈیا کی نقل و حمل کے لیے کیا جاتا ہے۔

- توانائی کی نقل و حمل:تیل اور گیس کی پائپ لائنوں میں ہائی پریشر اسٹیل پائپ کی متعلقہ اشیاء استعمال ہوتی ہیں۔

- HVAC (حرارتی، وینٹیلیشن، اور ایئر کنڈیشنگ):تانبے کے پائپ کی متعلقہ اشیاء ریفریجرینٹ پائپ لائنوں کو جوڑنے کے لیے استعمال کی جاتی ہیں، اور لچکدار جوڑ کمپن میں کمی کے لیے استعمال کیے جاتے ہیں۔

- زرعی آبپاشی:فوری کنیکٹرز چھڑکنے والی آبپاشی کے نظام کو اسمبلی اور جدا کرنے میں سہولت فراہم کرتے ہیں۔